Cut Edge Corrosion

Cut Edge Corrosion Treatment

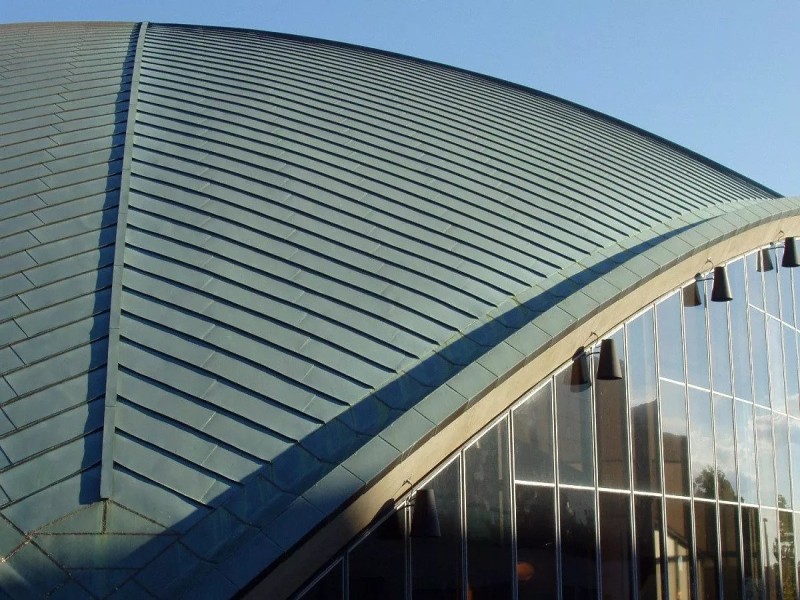

As commercial roofing contractors, we often find that metal cladding panels are susceptible to corrosion and weathering, especially at the point where the metal sheet ends or overlaps with another panel.

This type of corrosion is often referred to as cut edge corrosion treatment as the coated edge begin to de-laminate and cause serious product decay. If cut edge corrosion is not addressed quickly it’ll eat into the metal sheet causing leaks from roofing into the building. This could dramatically affect the value of the building and considerably increase maintenance costs.

As a rule, we would always recommend regularly coating your metal cladding in addition to frequent roof maintenance as an effective rust prevention method.

Our Cut Edge Corrosion Treatment & Repairs

After cut edge corrosion has been identified, the area must be first cleaned and prepared for treatment. Depending on the severity of the corrosion, loose paint, rust and corroded areas are often removed manually, to which a high-quality weatherproof sealant is then applied to the effective areas.

We’ll always ensure that all cut edge corrosion treatments & repairs are undertaken with little disruption to your property, business and the general public.

Our Cut Edge Corrosion is:

Available in all cladding colours

Able to reinforcement heavily deteriorated laps

Insurance backed with warranties available

Able to prolong early roof sheet replacement

Aesthetically pleasing

Our Promise

As a member of the NFRC our clients can also take advantage of a Co-partnership warranty. This independent warranty covers workmanship, materials and is insurance backed. In the event of any issues we’ll return within the time period and carry out the repairs. In the case of a material failure the manufacturer replaces the faulty material, compensating the contractor for his labour. If either parties are forced into liquidation/receivership the insurance company (QANW) fulfils the warranty